Engineer targets next frontier in lunar welding technology

by Clarence Oxford

Los Angeles CA (SPX) Apr 14, 2025

As plans to establish long-term human presence on the Moon and Mars accelerate, researchers are developing new techniques to enable construction in hostile, low-gravity environments. One such breakthrough effort is underway at The University of Texas at Dallas, where Dr. Wei Li is creating a virtual lunar welding platform to support the assembly of large-scale structures in space.

Dr. Li, assistant professor of mechanical engineering in the Erik Jonsson School of Engineering and Computer Science, is spearheading a NASA-funded project aimed at solving one of the most difficult aspects of extraterrestrial infrastructure: welding under extreme lunar conditions.

“As we try to return to the moon and reach Mars, keeping astronauts safe while achieving the missions is very important,” said Dr. Edward White, professor and department head of mechanical engineering. “Being in Earth’s orbit is a lot easier knowing that when things go wrong, we can make repairs and return safely. I’m really excited that Dr. Li’s research will help play an important role in making space travel safer and will enable us to successfully complete space missions.”

The three-year initiative, supported by a NASA Early Stage Innovations grant of up to $750,000, places Li among just six recipients nationwide recognized for their pursuit of high-impact space technologies. His work focuses on simulating and analyzing the unique challenges astronauts face when welding on the Moon.

“There are three main challenges for the astronauts working on the moon’s surface,” Li explained. “The moon has a very thin atmosphere, so there are steep temperature changes, from around minus 387 degrees Fahrenheit to 260 degrees Fahrenheit. There is also an extreme vacuum environment due to the thin atmosphere. Finally, the gravity on the moon’s surface is only about one-sixth that of the Earth. The extreme environment can complicate the reliable implementation of building or manufacturing large structures on the moon’s surface and can lead to manufacturing defects.”

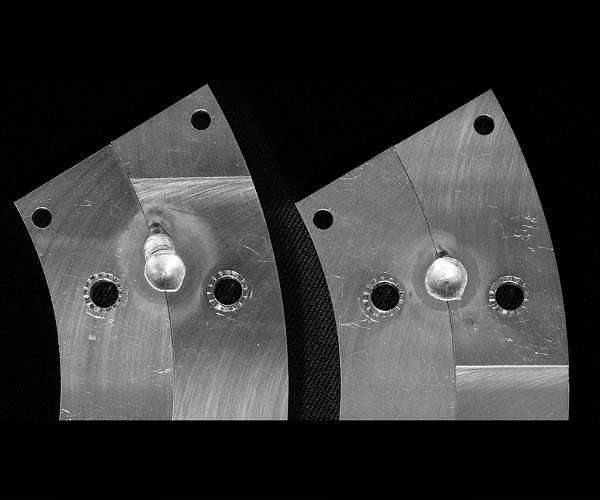

Welding operations must account for these volatile factors, which can introduce defects such as fractures and cracks that compromise the integrity of materials. Despite the difficulty, mastering welding in space is essential to NASA’s broader vision for constructing lunar bases and deep-space habitats.

“It would be very hard to establish regular machine shops on the moon’s surface to manufacture metal structures as we do on Earth,” Li said. “However, it could be possible to use spacecraft to ship metal components from the Earth to the moon, then deploy welding technology there to assemble the components into large structures that could enable the establishment of a human community.”

Li’s research includes simulations of various welding methods under lunar-like conditions, including electrical arc, laser, and electron-beam welding. A key tool in his laboratory is a directed energy deposition machine, commonly used in metal additive manufacturing. The platform also enables exploration of nonmetallic construction via fused deposition modeling, expanding its relevance to 3D printing in space.

Through the Comprehensive Advanced Manufacturing Lab, Li and his team will replicate lunar conditions at UT Dallas while collaborating with NASA researchers such as Dr. Fredrick Michael from NASA’s Marshall Space Flight Center. Their goal is to validate their simulation models using both ground-based testing and historical data from missions like Skylab.

This platform, once validated, could be adapted for other applications beyond the Moon, including Mars and the International Space Station, helping shape the future of in-space manufacturing and construction.

Related Links

School of Engineering and Computer Science at The University of Texas at Dallas,

Space Technology News – Applications and Research